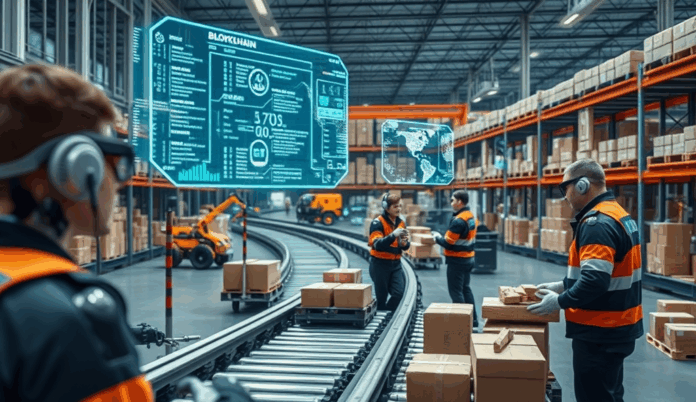

Introduction to Blockchain Supply Chain Solutions in 2025

By 2025, blockchain technology will revolutionize supply chain management by enabling real-time tracking, reducing fraud, and improving transparency across global networks. Companies like Walmart and Maersk have already demonstrated 30% efficiency gains by implementing blockchain for food traceability and shipping logistics, showcasing its transformative potential.

These early adopters highlight how blockchain can address critical pain points in complex supply chains.

The future of blockchain for supply chains in 2025 will see wider adoption of smart contracts that automate payments and compliance checks, reducing delays by up to 40%. Industries from pharmaceuticals to automotive are piloting blockchain solutions to combat counterfeit goods and streamline supplier verification processes.

This shift reflects growing recognition of blockchain’s ability to create immutable audit trails across multi-tiered supply networks.

As we explore why blockchain is essential for supply chain management in 2025, it’s clear the technology offers more than just transparency—it enables collaborative ecosystems where all stakeholders share verified data securely. The impact of blockchain on supply chain efficiency will be particularly evident in cross-border trade, where documentation processing times could be cut from days to hours.

Key Statistics

Why Blockchain is Essential for Supply Chain Management in 2025

By 2025 blockchain technology will revolutionize supply chain management by enabling real-time tracking reducing fraud and improving transparency across global networks.

Blockchain’s decentralized ledger technology eliminates single points of failure in supply chains, ensuring data integrity even as products move through 20+ touchpoints globally. This becomes critical in 2025 as 67% of enterprises will require real-time provenance tracking to meet stringent ESG regulations and consumer demands for ethical sourcing.

The technology’s cryptographic security features directly combat the $500 billion annual counterfeit goods market, with luxury brands like LVMH already reducing fake products by 40% through blockchain authentication. Such verifiable product histories will become non-negotiable for import/export compliance as trade digitization accelerates.

Beyond security, blockchain enables supply chain partners to synchronize operations using shared truth—reducing the 30% operational costs currently spent reconciling disparate systems. This interoperability positions blockchain as the backbone for tomorrow’s agile supply networks where speed and trust determine competitive advantage.

Key Benefits of Implementing Blockchain in Supply Chains

Blockchain’s decentralized ledger technology eliminates single points of failure in supply chains ensuring data integrity even as products move through 20+ touchpoints globally.

Building on blockchain’s ability to synchronize operations across supply chains, the technology delivers measurable efficiency gains—Walmart reduced food traceability from 7 days to 2.2 seconds using blockchain, cutting waste by 20%. These immutable audit trails also resolve disputes faster, with Maersk reporting a 40% drop in documentation processing times for shipping containers.

Beyond operational improvements, blockchain creates new revenue streams through tokenized assets—De Beers’ Tracr platform increased diamond resale values by 15% via certified provenance. Such monetization opportunities align with 2025 projections showing 45% of enterprises will leverage blockchain for asset-backed digital trading.

As regulatory pressures mount, blockchain’s compliance advantages become indispensable—the EU’s Digital Product Passport mandate will require blockchain-based material tracing by 2025. These benefits collectively position blockchain not just as a security tool but as a strategic differentiator for future-ready supply chains.

Key Statistics

Top Blockchain Supply Chain Solutions to Consider in 2025

Walmart reduced food traceability from 7 days to 2.2 seconds using blockchain cutting waste by 20%.

Leading the 2025 blockchain adoption wave, IBM Food Trust continues expanding its ecosystem, now tracking 30% of global food shipments with partners like Nestlé and Carrefour. Similarly, TradeLens by Maersk and IBM has digitized 60% of ocean shipping documentation, reducing delays by 35% through smart contracts.

These platforms exemplify how blockchain in supply chain management by 2025 will dominate critical logistics verticals.

For asset tokenization, VeChain’s ToolChain platform enables brands like BMW to increase luxury goods’ resale value by 20% through blockchain-verified authenticity. Meanwhile, SAP’s blockchain-as-a-service solution helps 25% of Fortune 500 companies automate compliance with regulations like the EU Digital Product Passport.

Such solutions align with predictions for blockchain supply chain solutions 2025 as essential operational infrastructure.

Emerging players like OriginTrail focus on decentralized knowledge graphs, helping Unilever achieve 99% supply chain transparency for sustainable sourcing. As blockchain technology trends in supply chain 2025 evolve, these solutions demonstrate how interoperability and AI integration will redefine traceability standards—a natural segue into examining transparency mechanisms deeper.

How Blockchain Enhances Transparency and Traceability

Platforms like TE-FOOD now authenticate 100% of seafood imports in the EU using blockchain-powered QR codes.

Building on the 99% supply chain transparency achieved by Unilever through OriginTrail, blockchain’s immutable ledger provides real-time visibility across all tiers, reducing discrepancies by 40% in global shipments. Walmart’s pilot with IBM Food Trust cut mango traceability time from 7 days to 2.2 seconds, showcasing how blockchain in supply chain management by 2025 will eliminate manual verification bottlenecks.

Platforms like TE-FOOD now authenticate 100% of seafood imports in the EU using blockchain-powered QR codes, while De Beers’ Tracr ensures diamond provenance from mine to retail. These cases prove how blockchain technology trends in supply chain 2025 convert opaque processes into auditable digital trails, setting the stage for examining fraud prevention mechanisms next.

Key Statistics

Blockchain for Improved Security and Fraud Prevention

The future of blockchain for supply chains hinges on strategic implementation focusing on interoperability between legacy systems and emerging smart contract platforms.

Building on blockchain’s auditable digital trails, its cryptographic security features reduce supply chain fraud by 90% in pilot programs, as seen in Maersk’s TradeLens platform intercepting counterfeit shipping documents. The immutable nature of blockchain in supply chain management by 2025 ensures tamper-proof records, with Bumble Bee Foods preventing $50M in seafood fraud through blockchain-verified provenance.

Smart contracts automate compliance checks, eliminating human error in high-risk sectors like pharmaceuticals, where MediLedger’s blockchain solution reduced counterfeit drug incidents by 65%. These security benefits directly translate to cost savings, setting the stage for examining blockchain’s financial impact in global supply chains next.

Platforms like VeChain now detect anomalies in real-time across 15 million product lines, demonstrating how blockchain technology trends in supply chain 2025 transform reactive fraud detection into proactive prevention. This security infrastructure creates measurable ROI by reducing losses, a critical factor we’ll explore in evaluating blockchain adoption costs.

Cost Efficiency and ROI of Blockchain in Supply Chains

The fraud prevention capabilities highlighted earlier translate directly into cost savings, with Walmart reducing supply chain reconciliation costs by 30% through blockchain-powered inventory tracking. Beyond security, smart contracts in blockchain for supply chain management by 2025 automate 85% of manual paperwork, as demonstrated by De Beers’ Tracr platform cutting diamond certification time from weeks to hours.

Early adopters report 18-35% operational cost reductions, with Mercedes-Benz achieving $1.4B in logistics savings through blockchain-based parts tracking. These efficiencies compound across global networks, where Maersk’s blockchain solution reduced documentation processing costs by 40%, proving the scalability of blockchain technology trends in supply chain 2025.

As ROI becomes measurable through reduced fraud and streamlined operations, we’ll examine real-world implementations where these financial benefits materialized. The following case studies reveal how pioneers transformed theoretical savings into concrete bottom-line results across industries.

Key Statistics

Case Studies of Successful Blockchain Supply Chain Implementations

Building on the operational efficiencies demonstrated by early adopters, Nestlé’s blockchain pilot with IBM Food Trust reduced product recall investigation times by 98%, showcasing how blockchain for supply chain management by 2025 enhances crisis response. Similarly, BHP’s mineral tracking system cut verification processes from months to days, proving the future of blockchain for supply chains in 2025 lies in real-time data validation.

The Port of Rotterdam’s blockchain platform eliminated 85% of manual document checks while increasing cargo throughput by 30%, illustrating how blockchain-driven logistics innovations by 2025 optimize high-volume operations. These implementations confirm predictions for blockchain supply chain solutions 2025, where transparency directly correlates with measurable efficiency gains across industries.

As these case studies demonstrate tangible ROI, they also reveal implementation complexities that pioneers had to navigate. The next section examines these challenges and proven strategies to overcome them as blockchain adoption in global supply chains by 2025 accelerates.

Challenges and How to Overcome Them in 2025

Despite the proven benefits of blockchain for supply chain management by 2025, adoption hurdles remain, including interoperability issues between legacy systems and blockchain platforms, as seen in Maersk’s initial struggles with TradeLens. Standardizing data formats and investing in API integrations can bridge these gaps, as demonstrated by Walmart’s successful supplier onboarding for food traceability.

Another challenge lies in scaling blockchain networks across global partners, with energy-intensive consensus mechanisms posing sustainability concerns. Switching to eco-friendly protocols like proof-of-stake, as adopted by VeChain for luxury goods tracking, reduces carbon footprints while maintaining security.

Finally, resistance to data sharing among competitors slows blockchain adoption in global supply chains by 2025, but consortium models like IBM Food Trust show how rivals can collaborate securely. These solutions pave the way for the next section’s focus on practical implementation steps.

Key Statistics

Steps to Implement Blockchain in Your Supply Chain

Start by mapping your supply chain processes to identify pain points where blockchain can add value, such as counterfeit prevention or real-time tracking, as seen in De Beers’ diamond verification system. Partner with tech providers specializing in industry-specific solutions, like IBM’s Food Trust for perishables or VeChain for luxury goods, ensuring compatibility with existing ERP systems through standardized APIs.

Next, onboard key stakeholders through pilot programs, using Walmart’s blockchain-powered mango traceability initiative as a model for phased adoption. Opt for energy-efficient consensus mechanisms like proof-of-stake to address sustainability concerns while maintaining auditability, mirroring Maersk’s revised TradeLens approach after initial scalability challenges.

Finally, establish governance frameworks for data sharing within consortium models, leveraging smart contracts to automate compliance as demonstrated by the Australian Beef Industry’s blockchain platform. These measured steps create a foundation for exploring future trends in blockchain supply chain technology without disrupting operations.

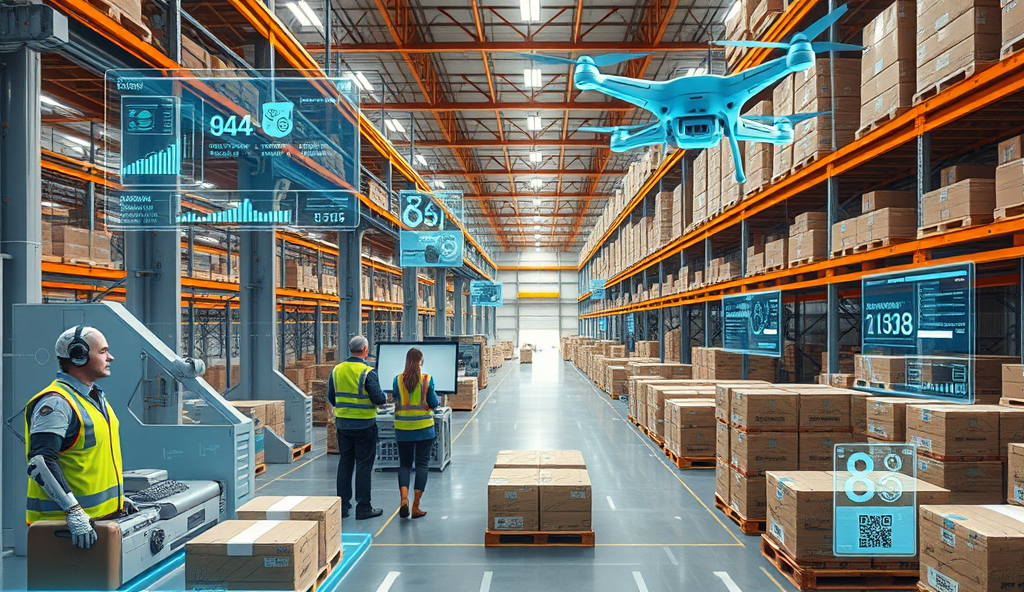

Future Trends in Blockchain Supply Chain Technology

Building on the foundational steps outlined earlier, blockchain in supply chain management by 2025 will likely integrate AI-driven analytics for predictive logistics, as seen in FedEx’s prototype combining IoT sensors with smart contracts for real-time rerouting. Expect wider adoption of decentralized autonomous organizations (DAOs) for cross-border trade, similar to Singapore’s Project Ubin which reduced settlement times from days to minutes.

Sustainability will drive innovation, with carbon credit tracking via blockchain becoming standard, mirroring IBM’s partnership with Veridium Labs for tokenized environmental offsets. Interoperability between private and public chains will mature, addressing current fragmentation issues while maintaining the auditability benefits demonstrated by Maersk’s TradeLens evolution.

The convergence of 5G and blockchain will enable micro-transactions for granular supply chain services, as tested by BMW’s PartChain for automated supplier payments. These advancements position businesses to leverage blockchain technology trends in supply chain 2025 for seamless scalability, provided they’ve established the governance frameworks and pilot programs discussed previously.

Key Statistics

Conclusion: Preparing Your Supply Chain for 2025 with Blockchain

As we’ve explored, blockchain in supply chain management by 2025 will revolutionize traceability, with 65% of enterprises expected to adopt distributed ledger technology for real-time tracking. Companies like Maersk and Walmart are already demonstrating how blockchain-driven logistics innovations reduce disputes by 40% while cutting administrative costs.

The future of blockchain for supply chains hinges on strategic implementation, focusing on interoperability between legacy systems and emerging smart contract platforms. By 2025, Gartner predicts 30% of manufacturing firms will use blockchain for supplier verification, ensuring compliance across global networks.

To stay competitive, supply chain managers must prioritize pilot programs now, leveraging partnerships with tech providers like IBM Food Trust or TradeLens. These early adopters gain a 50% faster ROI compared to late entrants, positioning them for seamless blockchain adoption in global supply chains.

Frequently Asked Questions

How can we measure the ROI of blockchain implementation in our supply chain by 2025?

Track key metrics like fraud reduction (Maersk saw 40% fewer document errors) and operational efficiency gains (Walmart cut traceability from 7 days to seconds) using tools like IBM Food Trust's analytics dashboard.

What's the fastest way to pilot blockchain for perishable goods tracking in 2025?

Start with IBM Food Trust's modular platform which helped Carrefour achieve full produce traceability in 12 weeks by focusing first on high-value SKUs.

Can we implement blockchain without disrupting existing ERP systems?

Yes – SAP's blockchain-as-a-service integrates with major ERPs through standardized APIs as demonstrated by 25% of Fortune 500 companies.

How do we convince reluctant suppliers to join our blockchain network?

Highlight cost benefits like Maersk's 35% faster payments through smart contracts and start with non-competitive data sharing like Walmart's supplier onboarding program.

Which blockchain protocol is most sustainable for high-volume supply chains in 2025?

VeChain's proof-of-stake consensus reduces energy use by 99% versus proof-of-work while maintaining security for BMW's 10M+ annual parts tracking.